HANNZ MOTROLproduct

INDXIA

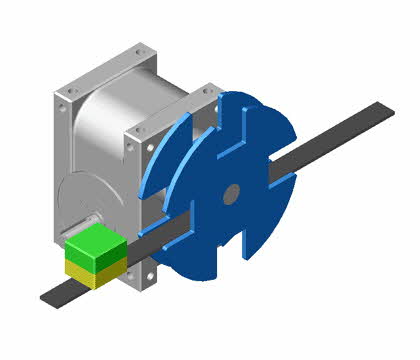

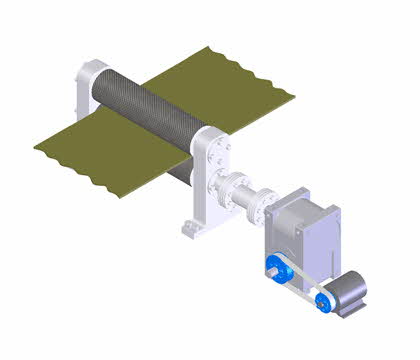

INDXIA HD series were developed for ‘faster, more accurate, and easier’ operation as a theme that a dividing unit in the structure of roller gear cam.

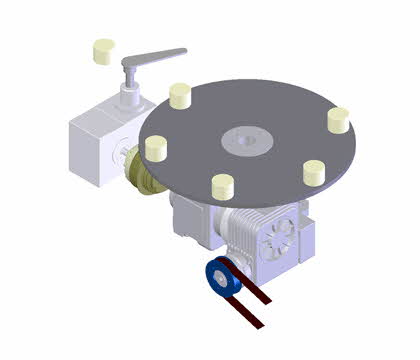

Output axis of the INDIA HD series has straight shaft type and flange type that can be diversely applied depending on the purpose of the usage. It is available to install the safety unit – torque shield – that protects the dividing units from being overloaded by using shaft and fixing table on the flange side.

With outstanding reliability, safety, and high speed of operation, it can be applied as a driving force of the auto equipment in the form of conveyor operation and rotation patterns.

Cost reducing effect is to be anticipated by the auto-production system based high productivity and reliability.

Characteristics of the product

-

Standardize the distance between

axes(Input and Output) from 45mm

to 170 mm (7 types) -

Standardize stop position

from 2stop to 16stop -

Output axis has straight shaft type and

flange type that can be diversely

applied depending

on the purpose of the usage. -

Applicable to all fields of

industry expecting the cost

reducing effect and improvement of

productivity through line automation

Code overview

Product code consists of the size, number of stop, angle, cam curve, cam rotation direction, input-output axis figure, and special specifications,

and there is a wide range of combination and complicated integration compared to general machines.

Therefore, it is needed to determine accurate product information by suggesting usage requirements clearly. Information of RPM and demand precision are required.

Please contact to the sales department of our company if you use Indexing drive for the first time

| Item | Example | Specific explanation |

|---|---|---|

| Format | HD |

Means the type of device

|

| Size | 080 |

Means the distance between axes between input and output axis (mm) - As for HD type model, 45 to 170mm are prepared. |

| Number of division | 08 |

Means the number of stop per output axis for each rotation of the input axis

- Up to 48 stops are available depending on the specifications of dwell of cam

|

| Index period | 27 |

Means the angle needed for the 1st stop on the cam of output axis.

- Index period is determined by the ratio of operating time: stoppage time (total tech time)

|

| Cam curve | 2 |

[1] MT : Modified Trapezoid

- MS curve is applied as a standard for cam curve Other cam curves and order-made specifications need to be separately inquired.

|

| Direction of Cam rotation | R |

R : Output rotates counter-clock wise when the input rotates in a normal direction

- If regular or opposite rotation of the driving source are not possible after applied to the interlocking devices such as a cases of attaching the plate cam, a care has to be taken on selection of rotation direction. |

| Number of dwell | blank |

No indication(blank) : 1 dwell (standard one)

|

| Specifications of the output axis | S |

S : Standard (Standard specifications)

|

| Option specifications | M |

M : Type installed with geared motor

- Worm reducer is an additional option. Please refer to the option specifications page. |

| Specification of the input axis | 3 |

1: Input axis in the T-surface only

|

| Mounting holes | VW |

VW : tapped hole on V and W surfaces - Tap hole on all surfaces specifications are indicated as A. Please notify us if selecting them in advance |

| Special specifications | /X |

Indicate whether there is special specification.

|