HANNZ MOTROLproduct

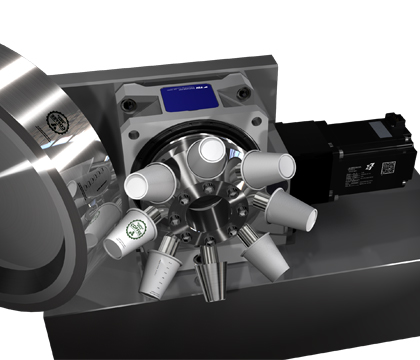

DynaStation

Dynastation GTB series is a high

precision servo reducer unit.

Solving the conventional problems of automation field,

Using original Zero backlash mechanism and Roller

Gear Cam structure, ealize high precision,

r light weight, and compact design.

Characteristics of the product

GTB High ratio type

Zero backlash mechanism without

abrasion compact high-strength body

-

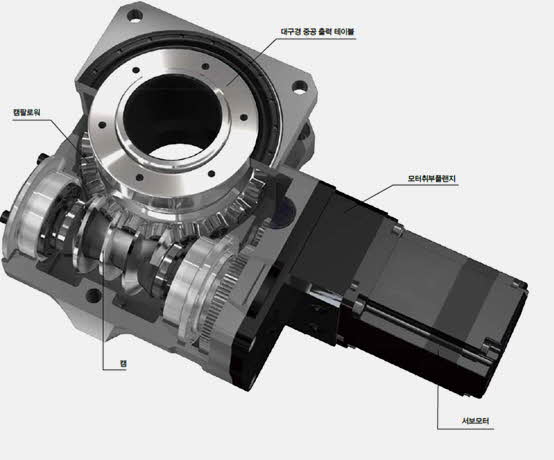

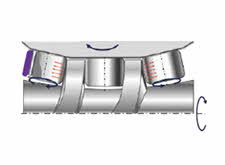

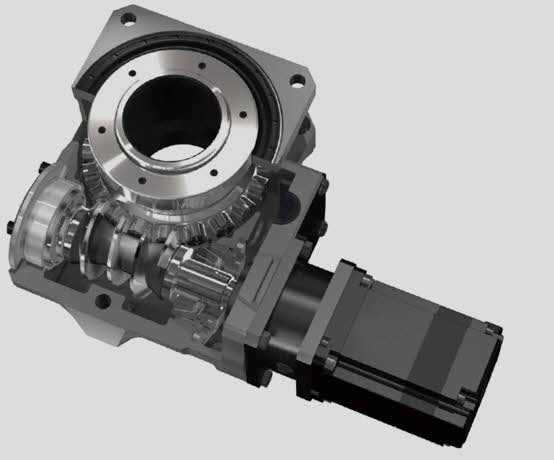

Roller gear cam reducer

The movement of the output is generated by the roller gear cam mechanism without backlash. with the preload, the roller gear cam makes a rolling contact, so it has zero backlash transfer characteristics as well as wear free and long term stable performance

-

BLACK FINISH high-strength body

The housing achieves high rigidity and compact deign by stress optimized design and high strength precision casting. The surface has a special black finish with excellent corrosion resistance.

GTB Motor direct type

Design that cope with two type

of reduction characteristics

-

Reduction ratio select system (PAT.P)

Product selection is available in two types: high ratio type for high torque and motor direct type for high accuracy.

-

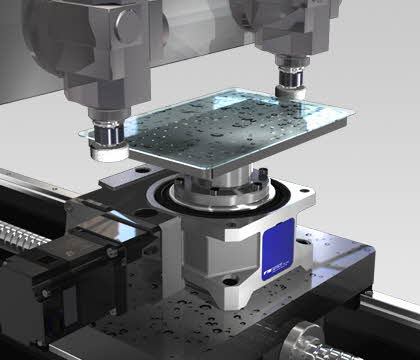

Stable vertical and

plane installationThe product can be installed in any direction, either plane or vertical. Except for the motor direction, the installable surface is arranged in all the other direction, so it can be used for various installation methods. In addition, since the front and rear mounting positions are the same, it is possible to arrange the position of the motor and the position of the output hole variously.

Product code

| Type | Size | - | MI Code | - | Installation position | - | Option |

|---|---|---|---|---|---|---|---|

| GTB | 63 | GGA10 | H | ||||

| GTB | 100 | JGA10 | V | TB |

| Type | Size | Reduction ratio (2digits) | Motor (3digits) |

|---|---|---|---|

| GTB | 40 | 45(high ratio) FG 15(motor direct) FD |

Please specify a code suitable for the motor to be installed. It is determined by the servo motor(refer to the next page). |

| 63 | 60(high ratio) GG 20(motor direct) GD |

||

| 80 | 60(high ratio) HG 20(motor direct) HD |

||

| 100 | 60(high ratio) JG 20(motor direct) JD |

| Installation position | ||

|---|---|---|

| Plane | H |

|

| Vertical | V |

|

| Etc | Z | Incline installation and product, rotate in any direction. |

| Option | ||

|---|---|---|

| Output table surface pin hole |

T | Table surface 1 ea refer to dimension drawing |

| Housing pin hole | B |

Top 2ea + Bottom 2ea refer to dimension drawing |

| Oil lubrication specification | Q | Plase contact us for details. |

| Special order | X |

Other specifications can be customized

(motors other than those listed in the list can also be installed) |

caution

- ※ Be sure to install a servo motor with brake type so that the table can safely stop at power failure if torque is applied due to gravity. etc.

- ※ When selection the motor, please make sure to satisfy all the requirements such as allowable torque motor driver regeneration resistance specification.

- ※ Read the manual procedures when assembling the motor.

- ※ Please contact us for further details.

GTB Line-up

| Model size | GTB40 | GTB63 | GTB80 | GTB100 | |||||

|---|---|---|---|---|---|---|---|---|---|

| Center distance | [mm] | 40 | 63 | 80 | 100 | ||||

| Output hollow diameter | [mm] | Φ25 | Φ50 | Φ75 | Φ85 | ||||

| Reduction ratio | i | 45 | 15 | 60 | 20 | 60 | 20 | 60 | 20 |

| Static rated torque | Ts[N·m] | 176 | 411 | 600 | 1341 | ||||

| Start-stop limit torque | Tu[N·m] | 94 | 210 | 307 | 880 | ||||

| Allowable average output speed | nm max[rpm] | 86 | 86 | 55 | 55 | 50 | 50 | 45 | 45 |

| Allowable maximum ouput speed | nm max[rpm] | 100 | 100 | 70 | 70 | 60 | 60 | 50 | 50 |

| Moment of inertia | J[kg·m2 X 10-4] | 0.17 | 0.263 | 0.4 | 0.817 | 1.52 | 3.214 | 4.08 | 10.39 |

| Back lash | [sec.] | 25 | 0 | 15 | 0 | 15 | 0 | 10 | 0 |

| Indexing accuracy | arc·sec arc·sec Max. |

90 | 60 | 40 | 40 | ||||

| Repeatability | arc·sec arc·sec Max. |

±10 | ±7 | ±5 | ±5 | ||||

| Permissible sxial load | Pa max[N] | 1100 | 1850 | 3632 | 4100 | ||||

| Permissible radial load | Pa max[N] | 740 | 1500 | 3100 | 3420 | ||||

| Permissible moment load | Mmean max[N·m] | 40 | 85 | 226 | 323 | ||||

| Average efficiency | % | 80 | 90 | 80 | 90 | 80 | 90 | 80 | 90 |

| Lubrication | Grease | Grease | Grease | Grease | |||||

| Weight (without motor) | [kg] | 3.5 | 3.3 | 6.2 | 5.9 | 14.1 | 12.9 | 25.2 | 24.3 |

Example of usage

-

Glass polishing machine

-

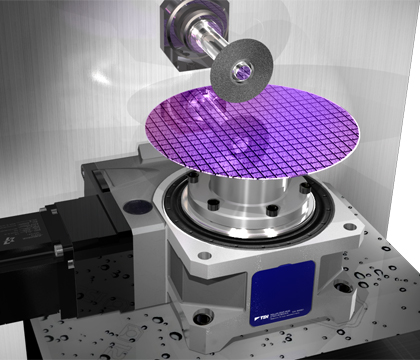

Wafer rotaion axis

-

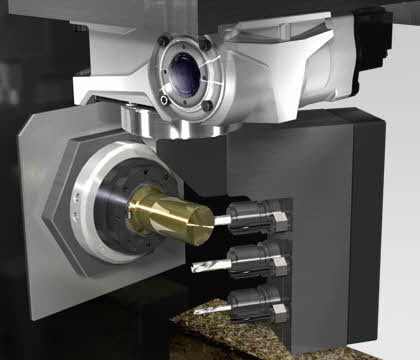

Lathe machine tool B-axis

-

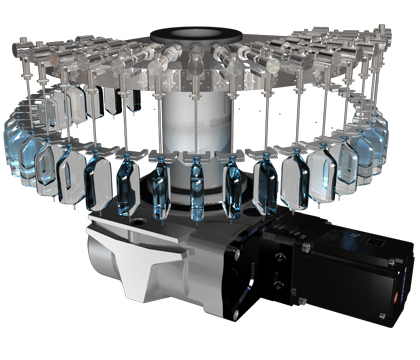

Filling machine

-

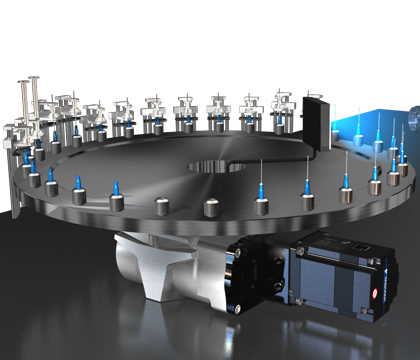

Needle assembly inspection

-

Rotary packaging machine